Heat integration on Dryer results in 290 kW energy savings

Heat recovery from Steam Boiler reduces 220 tonnes CO2 per year

How flue gas heat recovery solves Carbon Capture issues

Reliable waste heat recovery from corrosive flue gas

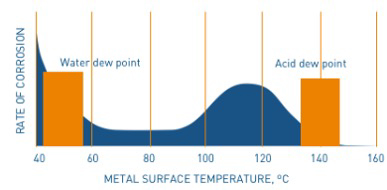

Low corrosion rates despite cooling through Acid Dew Point

How-to calculate the Acid Dew Point (ADP) of flue gas

When flue gas reaches a temperature below the acid dew point, acidic elements will condense. This could cause heat exchanger corrosion. Knowing the acid dew point of your flue gas enables you to select the appropriate materials for your heat recovery installation. ARTICLE 4 MINUTE READ What is the Acid Dew Point? The acid dew […]

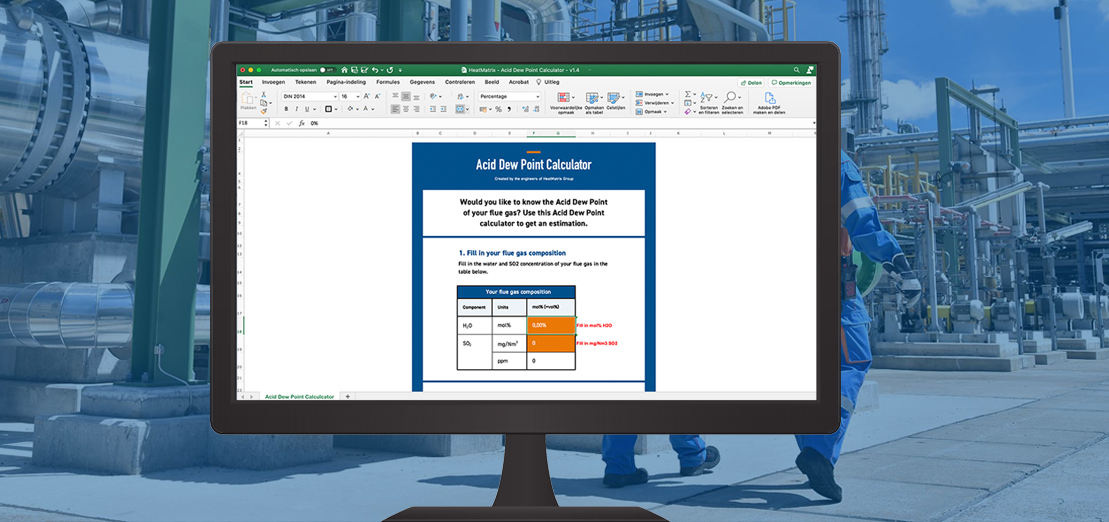

Calculate your Acid Dew Point with this free Excel tool

Acid Dew Point Calculator Quickly calculate the Acid Dew Point with this free Excel tool Acid Dew Point Calculation Would you like to know the Acid Dew Point of your flue gas? Use this handy Excel tool to quickly determine the Acid Dew Point of your flue gas or exhaust air. Acid Dew Point Calculation […]

Managing fouling in Polymer Economisers

Managing fouling in Polymer Economisers How the economiser cleans itself and is kept free from fouling Significant energy savings can be achieved when heat is recovered from hot flue and exhaust gases. When these hot flue and exhaust gases are fouling, management of this fouling is important in order to avoid heat exchanger blocking. The […]

Managing fouling in Polymer Air Preheaters

Managing fouling in Polymer Air Preheaters How the air preheater cleans itself and is kept free from fouling Significant energy savings can be achieved when heat is recovered from hot flue and exhaust gases. When these hot flue and exhaust gases are fouling, management of this fouling is important in order to avoid heat exchanger […]

Reduced flue gas temperature of an RTO from 200 to 76 °C