Waste heat recovery from Industrial Dryers

Your Industrial Dryer has additional waste heat recovery potential

Improve Dryer efficiency

Dryer efficiency can be improved with up to 20%, by using a polymer air preheater or economiser.

Lower CO2 emissions

Every 1% efficiency increase in your Dryer, results in 1% CO2 emission reduction.

Decrease fuel costs

The additional waste heat that is recovered is applied to heat up air entering the Dryer or heating up process water.

Waste heat recovery on Industrial Dryers is limited by fouling or corrosion

Blocked heat exchangers

Heat recovery from the exhaust air stream from a drying process is difficult due to the fouling behavior of dust and product contaminants present. It is a challenge to keep the exchangers clean and to prevent condensate flowing back to the Dryer.

Corroded heat exchangers

The moisture in the exhaust air in combination with corrosiveness of the dried material can create corrosion problems. Carbon steel and even stainless steel will quite often not provide the required corrosion resistance. In food applications the minimum standard is stainless steel.

How to recover more heat from your Dryer exhaust air

Use flue gas heat to warm up fresh drying air

The most important question is what to do with the recovered heat from the Dryer. The simplest and most economic solution is direct integration of the heat which means preheating the fresh air that enters the Dryer. The simultaneous presence of waste heat and need for heat in combination with short distances makes this the ideal solution. To prevent corrosion and deal with fouling, a polymer air preheater which is corrosion resistant and has good anti-fouling properties is applied.

Use condensation heat to warm up process water

Other heat users could also be present on your site, like process water, cleaning water or building heating. To prevent corrosion and deal with fouling, a polymer economiser which is corrosion resistant and has good anti-fouling properties is applied.

In-line cleaning

Waste heat recovery systems for Industrial Dryers

Polymer Air PreHeater

Warm up drying air by extracting heat from the exhaust air or flue gas. The air preheater is corrosion resistant & anti-fouling and easy to maintain and clean.

Stainless steel or Polymer Economiser

Warm up process water with waste heat from exhaust air or flue gas. The economiser is corrosion resistant & anti-fouling and is easy to maintain and clean.

CPVC producer Lubrizol

8% energy consumption reduction

Lubrizol is committed to enabling a sustainable world. To reduce their energy consumption on a drying process of CPVC, they wanted to recover heat from the outgoing drying air.

Before no heat was recovered from the drying air, because of the high hydrochloric acid content in it. When cooled down, through the water and acid dew point, hydrochloric acid is formed and corrosion occurs.

A HeatMatrix polymer air preheater was selected, because of its ability to handle corrosive exhaust air. Incoming cold air was heated from 10 to 56 °C, resulting in an energy saving of 169 kW. No corrosion issues were observed.

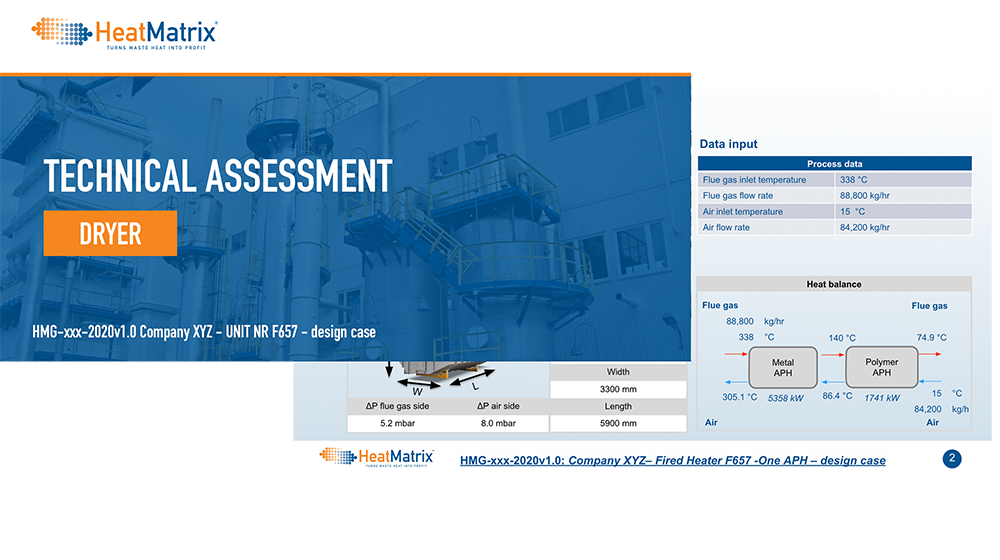

Technical Assessment of heat recovery on your Dryer

- Analysis of process data of your Dryer

- Minimal input data required

- Business case on your savings potential

FAQ's

How does an industrial Dryer work?

Industrial dryers are present in many different industrial segments like the chemical or food industry. They are installed to remove moisture from a product. Depending on the product type different type of dryers can be used: spray dryers for powder products or belt/drum dryers for products that have a different texture or composition. The product moisture is removed in an industrial dryer by evaporating the moisture. This evaporation step has a very high energy consumption.

What are industrial Dryers used for?

Industrial dryers are used for many different applications like spray drying of powder products like chemicals, ceramics or food products, belt drying of solids like waste-water sludge, drum drying of sand and minerals.

How does waste heat recovery on an industrial Dryer work?

In the majority of drying processes a wet exhaust air stream leaves the dryer. The air stream is at elevated temperature of >60ºC and has a high moisture content. Both the sensible and condensation heat can be recovered from the exhaust air stream using heat exchangers. The available heat sink (which medium you are going to heat up to what temperature) determines the selection of the most suitable technology to recover and reuse this waste heat.

Waste heat recovery options for industrial Dryers?

Dryers are energy intensive process steps in the chemical and food industry. Waste heat can be recovered from the wet exhaust stream leaving the drying process. Heat recovery of both the sensible and latent heat is possible. The recovered heat can be used to preheat the fresh air entering the drying process or used elsewhere in another thermal process. A combination of heat recovery with a heat pump is possible to lift the temperature of the waste to required levels.