Carlsberg

Flue gas of a biogas co-fired steam boiler cooled below the acid dew point without any corrosion issues.

Making the manufacturing process more sustainable

Within the Together Towards ZERO program, Carlsberg strives to make their breweries more sustainable. One of the steps taken in their Ukraine brewery is using a biogas fired steam boiler.

Sulphuric acid problems prevented additional heat recovery

Due to the usage of biogas, high concentrations of sulphur elements can be found in the flue gas. If the flue gas is cooled down, these sulphur components condense and form sulphuric acid which is very corrosive. To prevent this from happening, Carlsberg operated their system such that the flue gas was at a high temperature (>140 °C) leaving the stack. Additional heat present in the flue gas was not used.

HeatMatrix Polymer APH allowed cooling through the Acid Dew Point

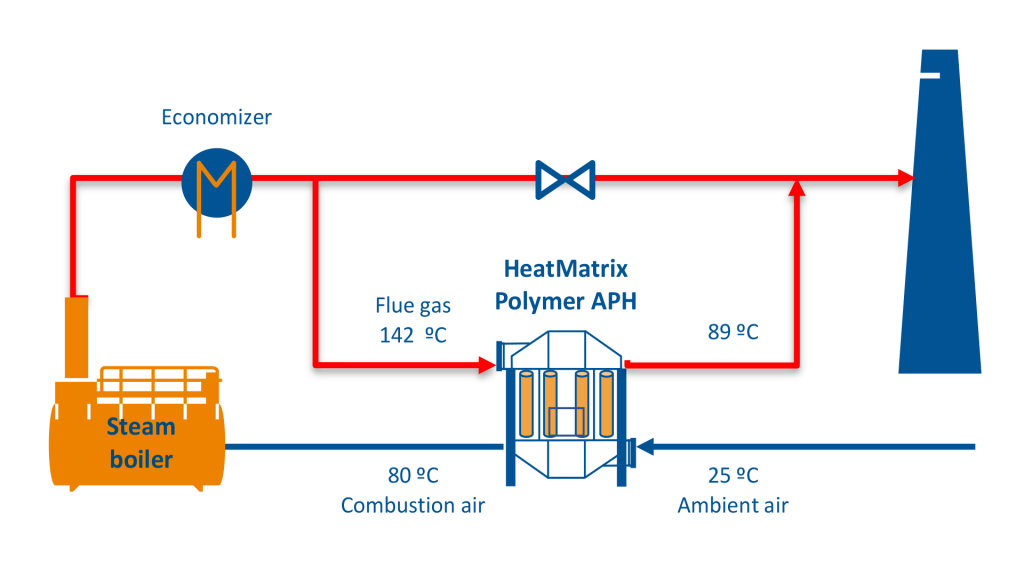

HeatMatrix installed a polymer air preheater which allowed Carlsberg to cool to temperatures below the acid dew point and achieve additional heat recovery on their steam boiler. There are no corrosion issues because of the corrosion resistance of the polymer used in the HeatMatrix air preheater. Based on the success in Ukraine, Carlsberg Serbia introduced the same solution on their biogas fired boiler.

Specifications

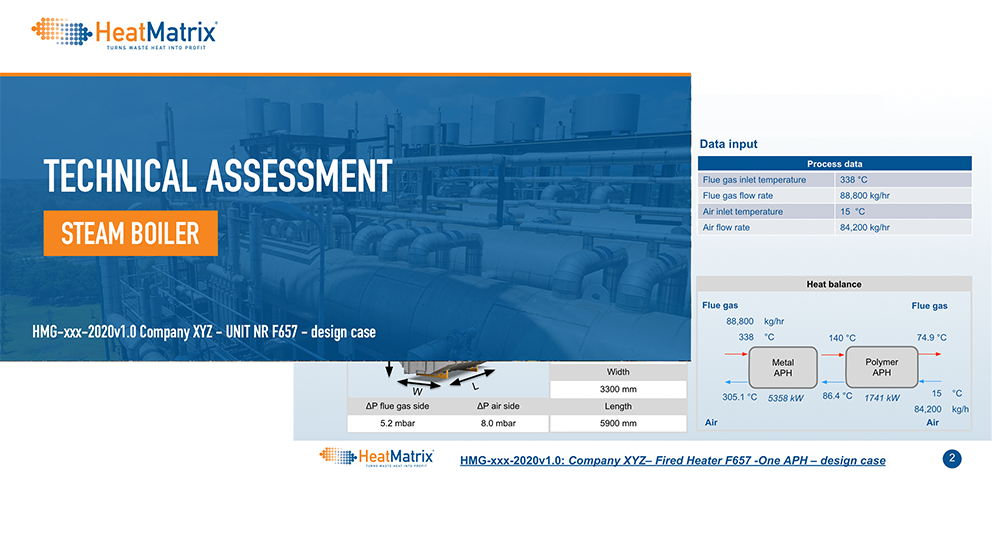

| Solution has a duty of | 290 kW |

| Boiler capacity | 20 TPH |

| Flue gas flow | 15,000 kg/hr |

| Temperature flue gas flow | 142 °C |

| SO2 concentration | 71.5 mg/Nm3 SO2 |

| Installed heat exchanger | HeatMatrix Polymer Air Preheater |

Boiler efficiency increased 4%

"HeatMatrix polymer Air PreHeater technology gave us the opportunity to recover additional heat from our steam boiler and make our process more sustainable. After installation of the polymer APH, our boiler efficiency increased with 4% and no corrosion issues occured since then."

For more than 10 years we design and deliver heat recovery systems for industrial factories

Want to recover more heat, just like Carlsberg?

Our process engineers assess the technical feasibility of additional heat recovery on your Steam Boiler, or any other thermal process. Your potential reduction in CO2 emissions, energy consumption and costs is determined by our experts.

- Analysis of process data of your steam boiler

- Minimal input data required

- Business case on your savings potential