Waste heat recovery from Fired heaters

Your Fired heater has waste heat recovery potential

Increase fired heater efficiency up to 95%

Fired Heaters are used in oil refining and in the chemical industry. They heat up product streams for the CDU, VDU, platformer, aromatics, hydrotreater and FCC. Most fired heaters have a thermal efficiency of around 85% – 90%. Solomon benchmarks competitiveness of refineries across the globe. Energy efficiency is one of Solomon’s KPI’s which is strongly influenced by the thermal efficiency of the fired heaters.

More CO2 emission savings

Chemical companies and oil refineries have to reduce their carbon footprint. Fired Heaters are huge energy users. A further decrease in flue gas temperatures, can contribute significantly to the reduction of energy usage and CO2 emissions. For a 100,000 barrel a day refinery an additional 26,000 tons of CO2 emissions can be avoided per year.

Additional waste heat recovery

By recovering more heat from flue gas, the usage of combustion fuel can be reduced. This means a reduction in energy costs. A 100,000 barrel a day refinery can reduce an additional 14 MW.

Heat recovery on Fired Heaters is limited by corrosion problems

Heat recovery is limited

Heat recovery on a Fired Heater can be realised with a waste heat boiler whereby additional steam is produced or with an air preheater where hot combustion air is produced. Heat recovery from flue gas using air preheating typically requires a balanced draft type Fired Heater. Guideline API 560 Annex 3 of the American Petroleum Institute describes proper design for an air preheating section on a Fired Heater. But not all heat can be recovered because of corrosion problems due to acid condensation.

Acid Dew Point

Fired Heaters are typically fired with refinery gas and/or fuel oil. Both fuels contain sulphur. The sulphur will be oxidized when burned to SOx which consists out 2-5% SO3 and the remainder will be SO2. When installing air preheating, it is important to protect the system for cold spot corrosion. The acidic part of the flue gas (SO3) starts to condense at the acid dew point (ADP). This condensation will take place in the coldest part in the process, being the air preheater; this leads to so called cold spot corrosion.

Amount of heat lost through flue

The flue gas temperatures of Fired Heaters after the existing air preheaters typically range from 140 to 250 °C. As a consequence, there is still a lot of additional energy savings possible once the cold spot corrosion problems can be overcome.

Advantages of recovering heat below the acid dew point with a polymer Air Preheater

-

Additonal waste heat recovery

Additonal waste heat recoveryCold spot corrosion problems limit heat recovery on Fired Heaters. The polymer air preheater of HeatMatrix combined with an (existing) metal air preheater enables heat recovery to a flue gas temperature below 100 °C and can boost heater efficiencies to 95% or higher.

-

Increased reliability of existing metal air preheater

Increased reliability of existing metal air preheaterThe polymer air preheater can be installed in series with the existing metal air preheater. The polymer air preheater protects the metal air preheater for cold spot corrosion and the metal air preheater protects the polymer air preheater for high temperatures. The combination allows heat recovery over a broad temperature range with a reliable operation.

-

Prevention of downstream corrosion

Prevention of downstream corrosionThe polymer air preheater can be installed upstream or downstream the ID fan. By-passes in both flue gas and air ducts can be considered for maximum reliability and flexibility. The downstream ducting and ID fan will not be impacted by cooling through the acid dew point because most of the acids are removed.

-

No influence of sulphur fluctuations in fuel

No influence of sulphur fluctuations in fuelSulphur fluctuations lead to fluctuations in acid dew point. The operation of the polymer air preheater is insensitive for these variations because it is corrosion resistant.

-

Protection against seasonal temperature changes

Protection against seasonal temperature changesThe polymer air preheater preheats the air before it enters the metal air preheater. Therefore the metal air preheater always operates at an elevated air temperature and seasonal influences are not posing a cold spot corrosion risk.

-

Elimination existing Steam air preheater

Elimination existing Steam air preheaterThe polymer air preheater replaces an existing steam air preheater. That means that you will not have any steam costs and maintenance costs.

Recovering heat beyond the acid dew point reduces the CAPEX and OPEX costs of future Carbon Capture & Storage (CCS) systems

Waste heat recovery systems for Fired Heaters

Polymer Air PreHeater

Heat up combustion air by extracting heat from flue gas. The air preheater is corrosion resistant & anti-fouling and is easy to maintain and clean.

Stainless steel or Polymer Economiser

Warm up boiler feed water, make-up water or process water with waste heat from flue gas. The economiser is corrosion resistant & anti-fouling and is easy to maintain and clean.

Refinery fired heater - CDU

4% increase of furnace efficiency

The refinery wants to decrease the carbon footprint of their operations. To reach this target waste heat recovery is one of their key focus areas. A lot of heat was being lost via the stack with the potentially corrosive flue gas. Our customer wanted to recover a part of this heat.

Previously further heat recovery was considered impossible due to the corrosive nature of the flue gas. When the flue gas is cooled, sulphuric acid is formed and corrosion occurs inside the heat recovery system. The HeatMatrix polymer Air preheater was selected because it can handle the formed sulphuric acid and make additional heat recovery possible.

After the HeatMatrix polymer Air preheater was installed, furnace efficiency increased with 4%. Corrosion rates downstream of the heat recovery system remained below 0.1 mm/year.

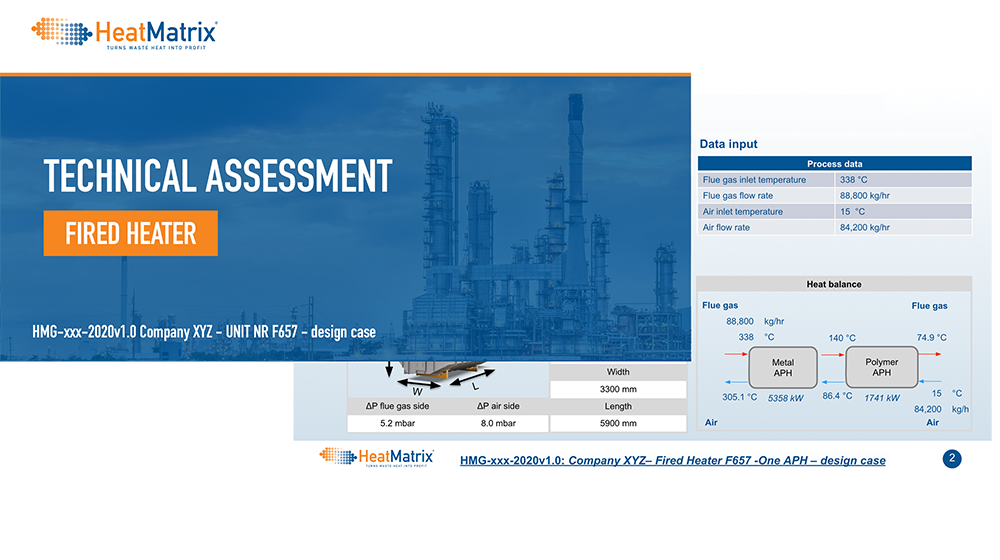

Technical Assessment of heat recovery on your Fired Heater

Our process engineers assess the technical feasibility of additional heat recovery on your Fired Heater. The potential reduction in CO2 emissions, energy consumption and costs is determined.

- Analysis of process data of your fired heater

- Minimal input data required

- Business case on your savings potential

FAQ's about Fired heaters

How does a fired heater work?

Which fired heater types are there?

Fired heaters can be classified by their geometry, burner positioning or draft design. Geometries can be cylindrical, rectangular in shape, in a vertical or a horizontal position. Burners can be positioned in the bottom or the wall of the fired heaters. The draft through a fired heater can be natural draft (without fans), forced (only air fan) or balanced draft (with an air and flue gas fan).

How does waste heat recovery on a fired heater work?

Recovery of waste heat on a fired heater is typically done using an air preheater. Downstream of the convection section the flue gases are guided through an air preheater. In the air preheater the flue gas heat is transferred to the combustion air. The preheated combustion air is fed to the burners. The elevated combustion air temperature lowers the required fuel input to the fired heater.

Benefits of waste heat recovery on a fired heater?

An air preheater on a fired heater can reduce the fuel consumption up to 20%. The lower the stack temperature, the higher the achieved fuel efficiency. Using a polymer air preheater in combination with a metal air preheater can result in a fuel efficiency of >95%.