CPVC producer Lubrizol

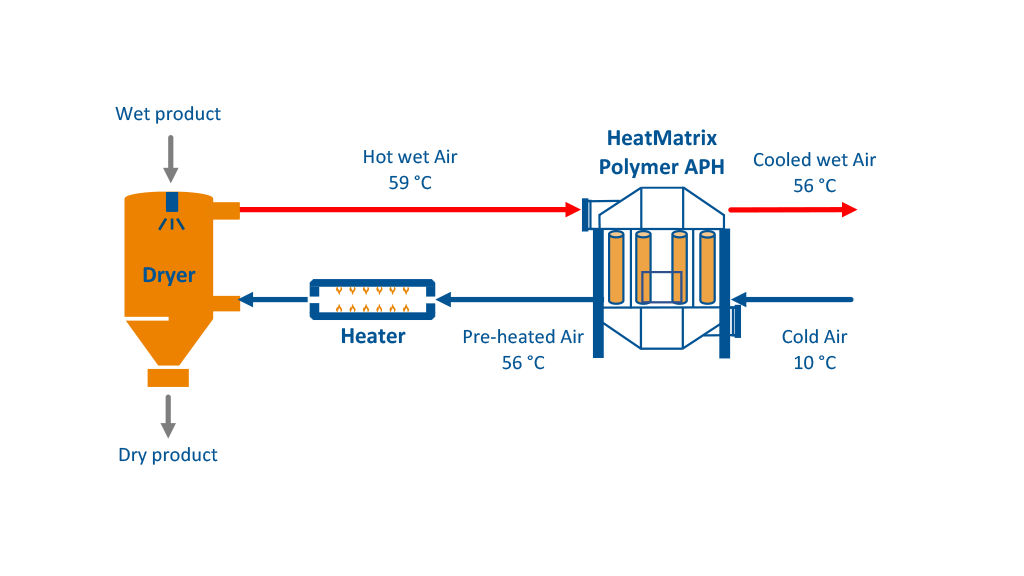

Corrosive exhaust air is cooled below the water dew point resulting in a reduction of the energy consumption of the dryer of 8%.

HeatMatrix Polymer Air Preheater

Previously no heat was recovered from the exhaust air of the dryer, because of the high hydrochloric acid content in it. When cooled down, through the water and acid dew point, hydrochloric acid is formed and corrosion occurs. A HeatMatrix polymer air preheater was selected, because of its ability to handle corrosive exhaust air.

Energy savings of 170kW

Incoming cold air is heated from 10 to 56 °C, resulting in an energy saving of 170 kW. Corrosion free heat recovery is achieved.

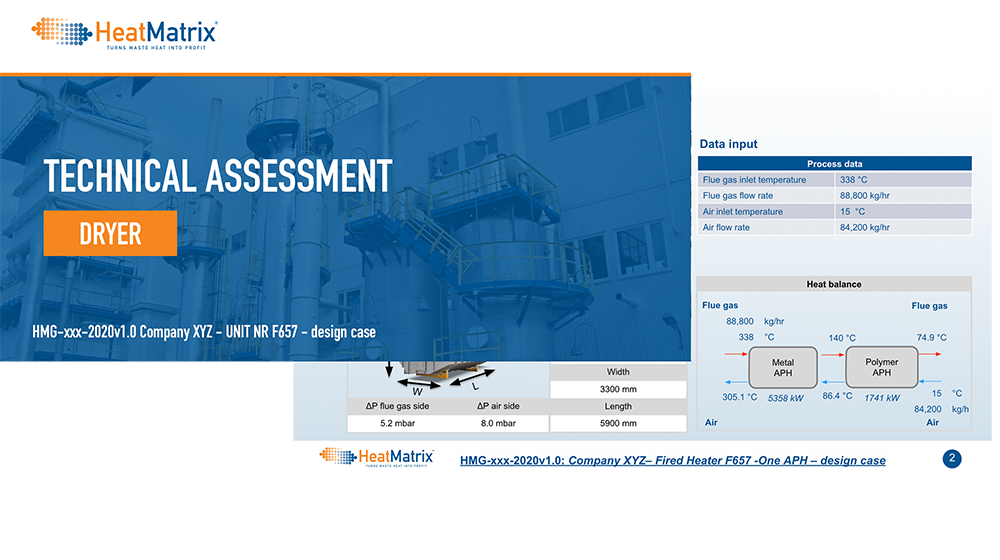

Specifications

| Solution has a duty of | 170 kW |

| Flue gas flow | 13,000 kg/hr |

| Temperature flue gas flow | 59 °C |

| HCl concentration | 100 mg/Nm3 |

| Installed heat exchanger | HeatMatrix Polymer Air Preheater |

8% energy reduction on dryer

"The HeatMatrix polymer Air PreHeater has proven to be a robust solution. After installation of the polymer APH system, the energy consumption of our dryer decreased with 8% without any corrosion issues."

For more than 10 years we design and deliver heat recovery systems for industrial factories

Want to recover more heat, just like Lubrizol?

Our process engineers assess the technical feasibility of additional heat recovery on your Dryer, or any other thermal process. Your potential reduction in CO2 emissions, energy consumption and costs is determined by our experts.

- Analysis of process data of your Dryer

- Minimal input data required

- Business case on your savings potential