Polymer Air PreHeater - APH

- Waste heat recovery system for flue gas or exhaust air

- Heat up combustion or drying air

- Corrosion and fouling resistant

Common air preheater problems

Corrosion and fouling problems with air preheaters limit waste heat recovery from flue gas or exhaust air

Heat exchanger corrosion and rust

Flue gases from burning fuels like refinery gas, fuel oil, off gases, blast furnace gas, oil, coal, biogas and biomass contain acidic elements. When you recover all the heat you will cool the flue gas or exhaust air through the acid dew point. Acids will then condensate which leads to corrosion in conventional metal air preheaters and in the rest of the installation.

Blocked heat exchangers

When exhaust air is cooled too deep, fouling may start to accumulate quicker and can eventually lead to blockage of your heat exchanger.

Waste heat can be recovered with air preheaters made with polymer

Heat up combustion air

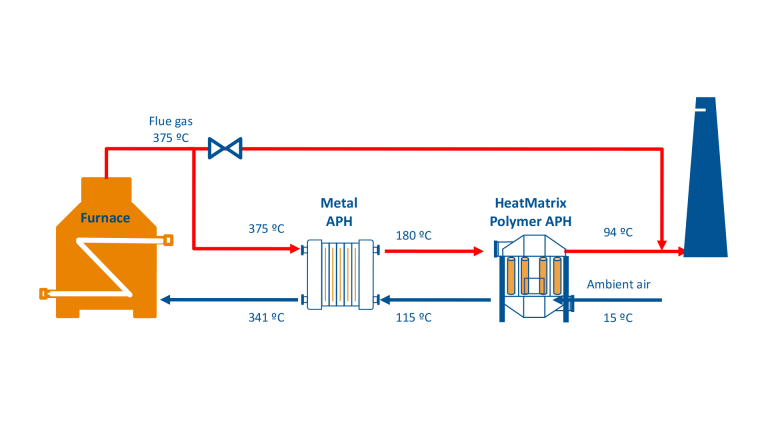

The polymer air preheater is used for combustion air preheating on thermal processes. Ambient air is heated up and is fed to the burners. By burning hot combustion air instead of cold combustion air, less fuel is needed to achieve a certain duty. Due to acid condensation, heat recovery from flue gases can be demanding.

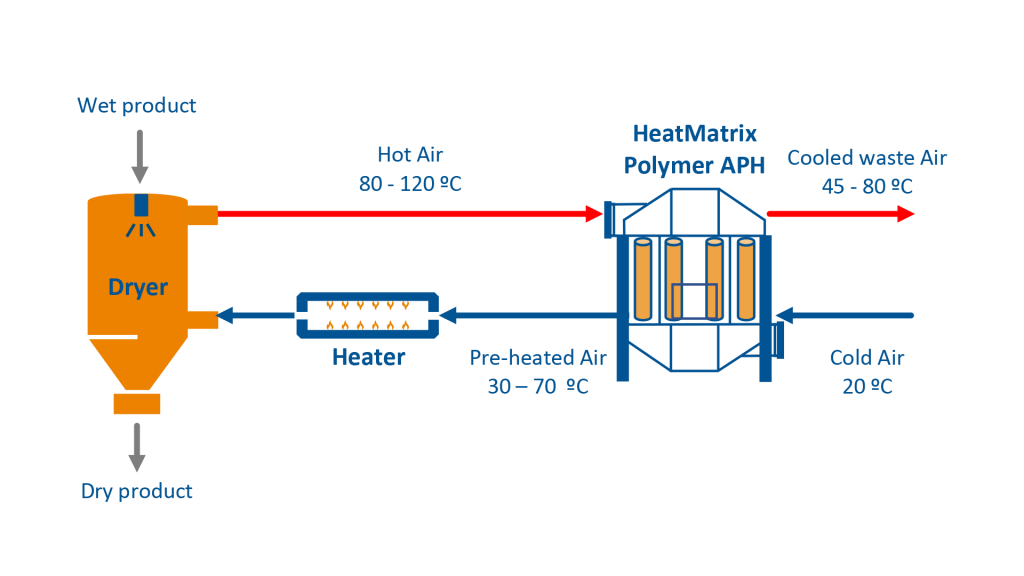

Heat up drying air

The heat from exhaust air is recovered and used to preheat fresh ambient air entering the dryer. This saves fuel on the fresh air heater. Due to the high humidity and presence of dust, heat recovery from drying processes can create corrosion and fouling problems.

Benefits of Polymer Air PreHeaters - APH

-

Resistant to corrosive flue gas and exhaust air

Resistant to corrosive flue gas and exhaust airThe air preheater contains polymer tube bundles, through which the flue gas or exhaust air flows. The polymer is resistant to the acids that are formed. The polymer can handle H2SO4, HCl, HF, H3PO4 and others.

-

Prevention of corrosion in duct and stack

Prevention of corrosion in duct and stackUp to 80% of the acids will be condensed and removed from the flue gas by the polymer air preheater. This lowers the acid dew point substantially and prevents down stream corrosion.

Learn more about Polymer Air Preheaters

Patented Polymer Honeycomb Technology (PHT)

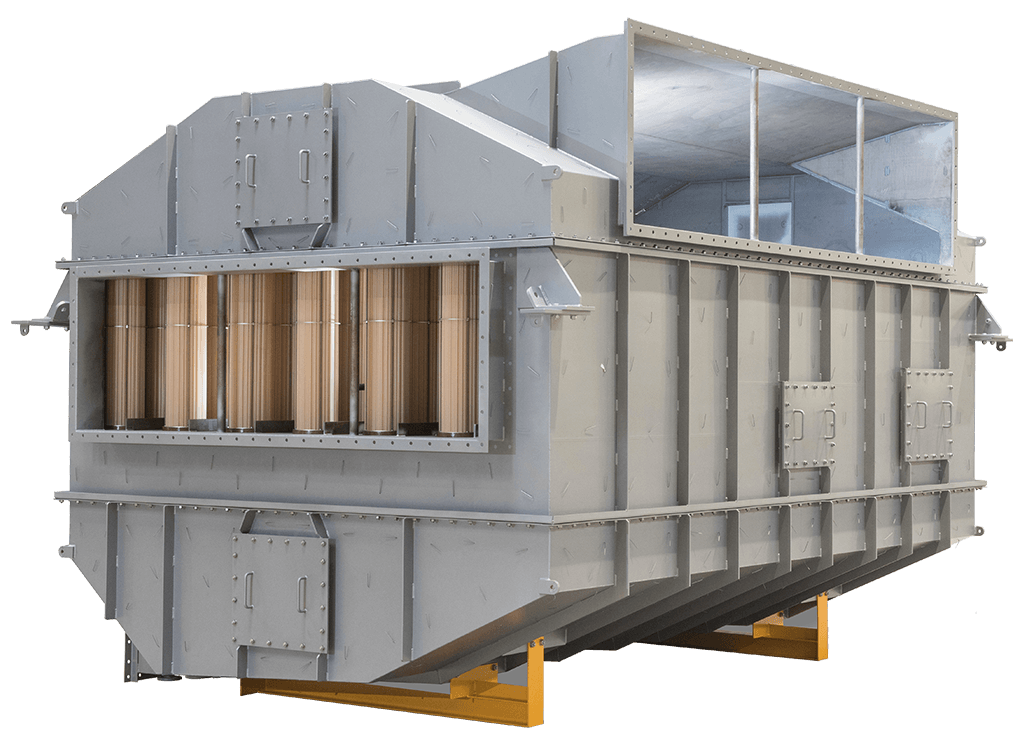

Standard modules

The polymer air preheater consists of polymer tubes that are combined into standardized bundles. The bundles are installed in a compact metal casing.

Stability

The individual polymer tubes are interconnected using the Polymer HoneyComb Technology (PHT). This stabilizes the tubes for flow induced vibrations.

Compact and light weight

The 1.5 meter long bundles provide an intense heat exchange process. The PHT technology creates a countercurrent flow path for hot and cold gas streams. Therefor the air preheater is compact and light weight.

Heat exchanger design

The Polymer Air Preheater is designed for perfection

Even distribution of temperature

The polymer air preheater is designed using Computational Fluid Dynamics to ensure homogeneous air and flue gas distribution which ensures maximum performance of the air preheater under all conditions. Due to the even distribution of the flow, the temperature of the flue gas coming out of the air preheater is everywhere the same.

No dead zones

The vertical downward flow of flue gas or exhaust air ensures proper drainage of condensate. Both gas and condensate flow in the same direction assisted by gravity. There are no baffles or turns where fouling can accumulate.

Disengagement of acids and flue gas

Liquids are separated from the cooled flue gas flow in the bottom segment of the polymer air preheater. Water and acids are removed via the drain in the waste heat recovery system

Polymer air preheater cleaning and maintenance

Cleaning with water

The polymer air preheater can be easily cleaned manually when you open the top lid during a stop. There is also the possibility to install an inline cleaning system. Each bundle has its own spray nozzle, which can clean the bundle during operation.

- Cleaning frequency adjusted based on process conditions

- Bundle design and drain for easy drainage of washing liquids

- Smooth polymer surface prevents fouling

Maintenance

Maintenance of the polymer air preheater is easy.

- Regular visual inspection during stop is sufficient

- Retraction of the polymer bundles for washing or inspection in case of heavy fouled equipment

- The low weight of the bundles make it easy to handle them without a crane

Learn more about the maintenance and cleaning of the Polymer Air Preheater

MANUAL

Download Operating & Maintenance manual

INFOSHEET

Condensate treatment

Technical Polymer Air Preheater details

Polymer Air Preheater operating range

| F: | 5.000 - 500.000+ kg/hr |

| Tdesign: | 200 °C |

| Pdesign: | 150 mbar |

| ΔP: | ~6 mbar |

For operating temperatures above 200 ºC a combination of a metal air preheater in series with a polymer air preheater is applied.

Polymer Air Preheater Thermal expansion

The polymer air preheater is designed in such a way that the polymer bundles can thermally expand without stresses acting on the polymer tubes. The air preheater can be heated-up and cooled down instantaneously. There is no time dependent heating profile required.

Polymer Air Preheater Dimensions

The design of the polymer air preheater is based on the requirements of a client and process data of a specific situation. The dimensions are derived from the hot and cold flows, temperatures, composition of the flows. The nozzle orientation is flexible and matched to the ducting design.

Polymer Air Preheater Materials

The casing has four segments (see schematic overview above). The construction material can be selected for each segment of the air preheater individually based on the application.

Receive all technical details required for the installation concept

INFOSHEET

Polymer Airpreheater Installation concepts

Polymer Air Preheaters are used in these industries and thermal processes

Thermal Processes

Your path to lower CO2 emissions, energy consumption and costs

Technical assessment

Our process engineers assess the technical feasibility of additional heat recovery on your process. The potential reduction in CO2 emissions, energy consumption and costs is determined.

Heat exchanger design and Business Case

A proposal is made with all technical details and economic assessment with payback time. You have everything you need for budget approval.

Realize project delivery

FAQ's

What is the function of an Air preheater?

An air preheater is a heat exchanger type that preheats combustion air by recovering heat from flue gas that leaves the combustion process. Alternatively, an air preheater can be used to recover heat from exhaust air from a dryer or oven and preheat the inlet drying air. The working principle of an air preheater is that the flue gas heat is directly integrated in the combustion process. Both flue gas and combustion air are present at the same time with approximately the same flow rates. The same principle applies for the exhaust air from and inlet air for a dryer or oven. Therefore, an air preheater is an economically attractive way to recover heat.

What are the working principles of an Air preheater?

An air preheater is a gas gas type heat exchanger. How an air preheater works, inside the heat exchanger heat is being exchanged between hot flue gases or exhaust air and cold combustion air. This heat exchanger consists of 4 sections. Hot flue gas enters via the top section and flows downwards through the tubes to the bottom section. Cold combustion air enters in the lower middle section and flows upwards between the tubes. It collects the heat from the hot flue gases and leaves via the upper middle segment. The preheated combustion air can be used in any industrial thermal combustion or drying process.

How to calculate Air preheater efficiency?

The thermal effectiveness of an air preheater is calculated by dividing the difference of the air inlet and air outlet temperature of the air preheater by the difference of the flue gas inlet and air outlet temperature of the air preheater.

How to calculate Air preheater design?

Heat transfer depends on the heat transfer coefficient, transfer area and logarithmic mean temperature difference between the inlet air and flue gas side. The heat transfer coefficient is a result of velocities, Reynolds and flue gas composition. These calculations are complex and take into account many factors. If you have specific situation where you want to know what kind of air preheater you need to employ, please contact us and we will be happy to do a technical assessment.

How to calculate Air preheater leakage?

Leakage in an air preheater is the result of the pressure difference between the air and flue gas side. Typically, air side pressures are higher resulting in a small air leak rate to the flue gas side. Leakage of air can be detected by analyzing the oxygen concentration in the flue gas downstream the air preheater. Air preheaters typically have a leakage that is <0.5%. This small amount is not impacting the operation of the air preheater or combustion process. Higher leak rates would lead to loss of combustion air and will result in a lower combustion capacity because insufficient air reaches the burners.

How is Air preheater corrosion and blocking prevented with polymer?

Heat exchanger corrosion prevention

Flue gas can contain corrosive elements, causing heat exchangers to rust. Polymer bundles in heat exchangers prevent corrosion. The polymer bundles contain polymer tubes that are interconnected and form a strong honeycomb structure.

Heat exchanger blocking prevention

Heat exchanger blocking is caused by accumulating fouling elements in the heat exchanger. Fouling elements don't bind well to polymer surface. The ability of polymer to cope with corrosive and fouling elements makes it very well suited for the application in heat exchangers to recover industrial waste heat.

Difference Air preheater and Economiser?

Heat recovery from flue gases can be done using air preheaters or economisers depending on the application of the waste heat. With an air preheater the recovered heat is used to preheat the (combustion) air. Economisers use the flue gas waste heat to preheat boiler feed water or process water.