Industrial Cookie Bakery

Heat recovery from a tunnel oven reduced gas consumption with 20%.

Heat recovery from fouling baking vapours

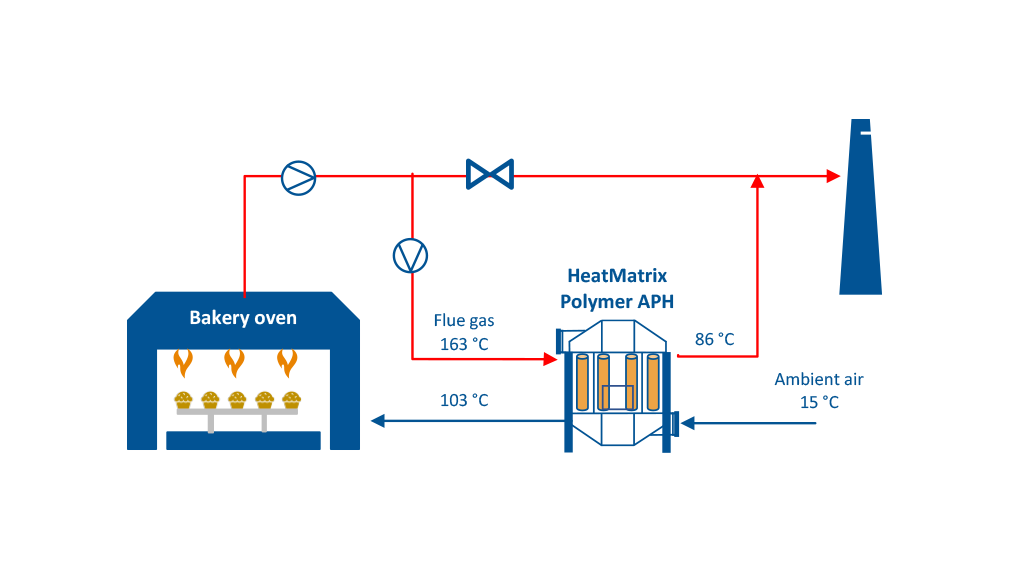

The industrial bakery has the ambition to reduce energy consumption. In the production process of cookies many fatty ingredients are used like butter and chocolate. In the oven fouling baking vapours are extracted and currently released to the atmosphere at high temperature. The bakery would like to recover heat from these vapours to reduce overall energy consumption.

HeatMatrix Polymer Air Preheater

Because of the smooth surface of the polymer tubes the HeatMatrix polymer air preheater has a low tendency to foul. This aspect in combination with an in-situ cleaning system makes it the perfect combination for heat recovery at this bakery. A polymer air preheater was installed and cools down all the baking vapours from the oven.

20% reduction of oven gas consumption

Circulation air for the oven is preheated from 15 to 103°C, which results in a heat recovery of 140 kW and a reduction of the oven gas consumption of 20%.

Specifications

| Solution has a duty of | 140kW |

| Flue gas flow | 6,100 kg/hr |

| Temperature flue gas flow | 163 °C |

| Fouling | Sugars and fatty acids |

| Installed heat exchanger | HeatMatrix Polymer Air Preheater |

Oven gas consumption reduced by 20%

"Installing the HeatMatrix polymer Air PreHeater resulted in energy savings of 20% in natural gas consumption. Furthermore, the temperature distribution of our oven improved, which resulted in more stable operation and a reduction in baking time."

For more than 10 years we design and deliver heat recovery systems for industrial factories

Heat recovery scan for your Bakery

Our heat recovery experts help you determine the most interesting opportunities for waste heat recovery. You receive an overview of options.

- Discover your saving opportunities

- Minimal input data required

- Business case on your savings potential