Brick manufacturer

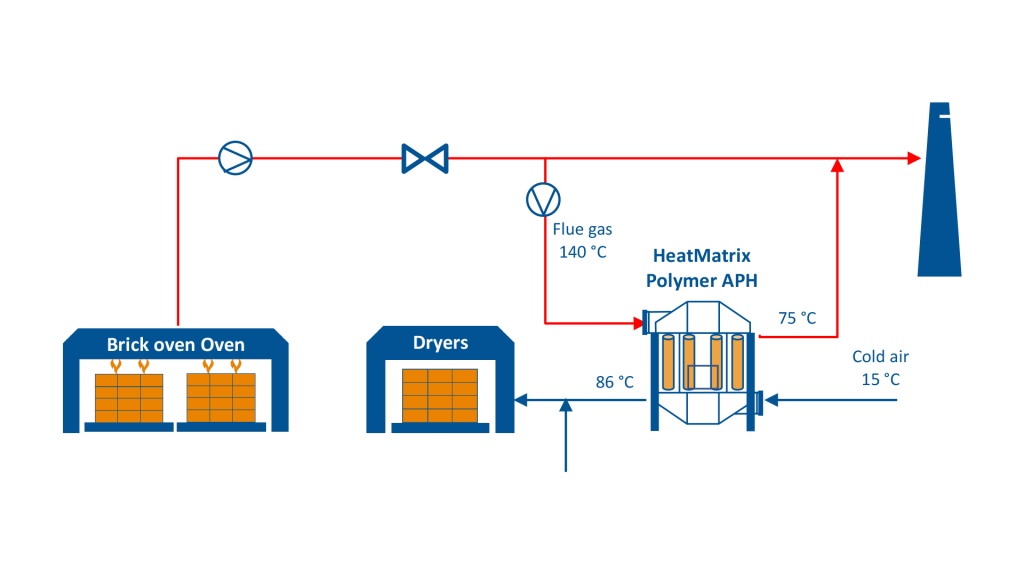

Heat recovery from flue gas of a brick oven to preheat drying air showed a heat recovery potential of 590 kW with a payback period of 3 years.

Heat recovery in the ceramics industry

In the ceramics industry flue gases are released from the oven at a temperature of 150 to 250 °C. This flue gas is sent directly to the atmosphere and a significant amount of energy is lost. Main reason for not recovering heat from this flue gas is the presence of sulphur oxides, chlorides, fluorides, soot and dust. When the flue gas is cooled down, an acidic condensate is formed which causes corrosion and the rate of fouling increases.

HeatMatrix Polymer Air Preheater

The HeatMatrix polymer air preheater is a robust solution for the corrosive and fouling flue gases encountered in the ceramics industry. The inline cleaning system allows frequent water washing which ensures an optimal performance of the air preheater at all times. The air preheater is insensitive for corrosion due to the used polymers. The recovered heat is typically used to heat-up the air going to the drying chambers.

Heat recovery from fouling and corrosive flue gases

The HeatMatrix polymer air preheater is able to handle both corrosion and fouling aspects of the flue gas. The installed cleaning system in combination with the smooth surface of the polymer makes it possible to clean the heat exchanger within 3 minutes in case particles or dust have accumulated. A business case was prepared to use the recovered heat for preheating of the incoming cold air at the dryer section. A overall payback period of 3 years was determined.

Specifications

| Solution has a duty of | 590 kW |

| Capacity | 45 MM bricks/year |

| Flue gas flow | 30,000 kg/hr |

| Temperature flue gas flow | 140 °C |

| Acidic components | H2SO4, HCl, HF |

| Proposed heat exchanger | HeatMatrix polymer APH |

No corrosion and fouling problems

"The HeatMatrix polymer Air PreHeater is a good solution for heat recovery from ovens within the ceramics industry. In the pilot no corrosion was observed and fouling was easily removed from the HeatMatrix polymer APH. We expect that the system will play an important role in the sustainability roadmap of our industry."

For more than 10 years we design and deliver heat recovery systems for industrial factories

Heat Recovery Scan for your bricks or tiles plant

Our heat recovery experts help you determine the most interesting opportunities for waste heat recovery. You receive an overview of options.

- Discover your saving opportunities

- Minimal input data required

- Business case on your savings potential