Paper Mill Europe

More sustainable manufacturing proces

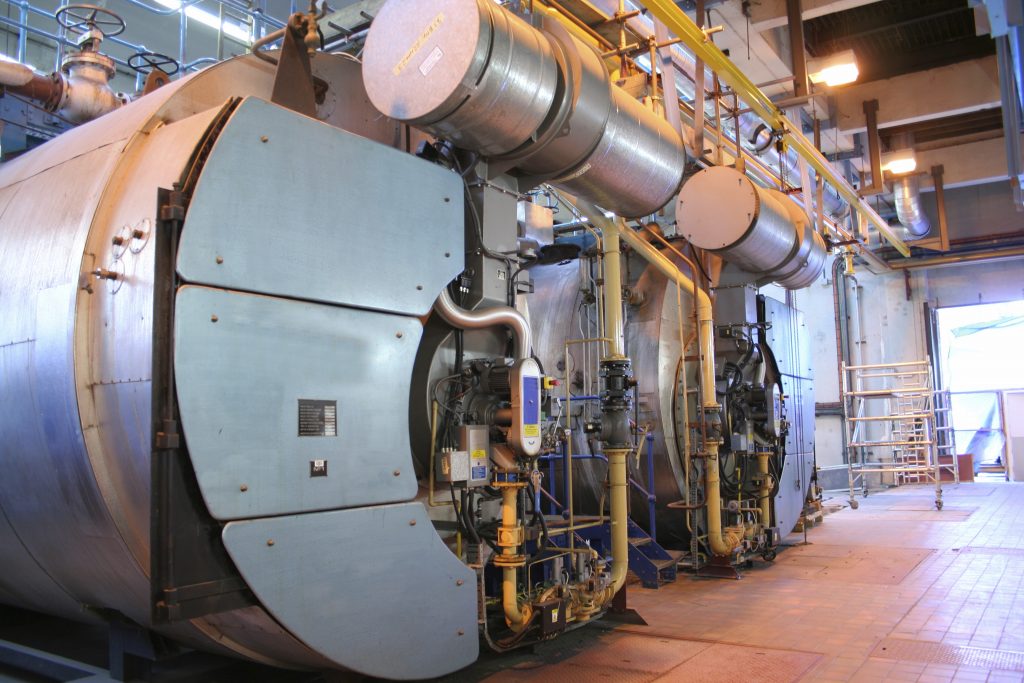

This paper manufacturer has the ambition to make their production processes more sustainable. Their steam boiler is being co-fired with biogas. Currently, heat recovery from the flue gas of this boiler is limited due to the potentially corrosive nature of the flue gas.

Study on how to recover more heat

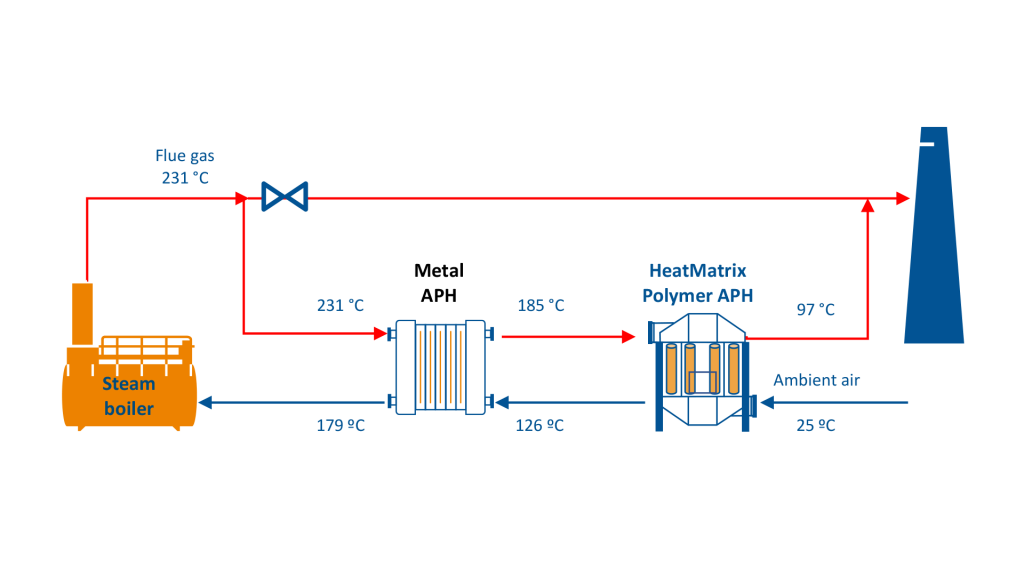

Conventional metal air preheaters are not suitable for deep cooling of the flue gas because the acids in the flue gas will condense. Heat recovery through a combination of a metal and and a polymer waste heat recovery system was designed. With this system, flue gas may be cooled down through the acid dew point to preheat the combustion air.

6% boiler efficiency increase

Combustion air will be preheated from 25 to 179 °C. Thanks to the combination of a metal and a polymer air preheater, more heat can be recovered without corrosion issues.

Specifications

| Solution has a duty of | 760 kW |

| Capacity | 16 TPH |

| Flue gas flow | 18,500 kg/hr |

| Temperature flue gas flow | 231 °C |

| SO2 concentration | 200 mg/Nm3 |

| Proposed system | Combinaton of a polymer and metal APH |

6% boiler efficiency increase

"We have been focusing on sustainable production for many years now. The energy lost via the flue gas of the steam boiler caught our attention. This study shows the potential of the HeatMatrix polymer Air PreHeater to overcome our corrosion challenges and recover a significant amount of waste heat."

For more than 10 years we design and deliver heat recovery systems for industrial factories

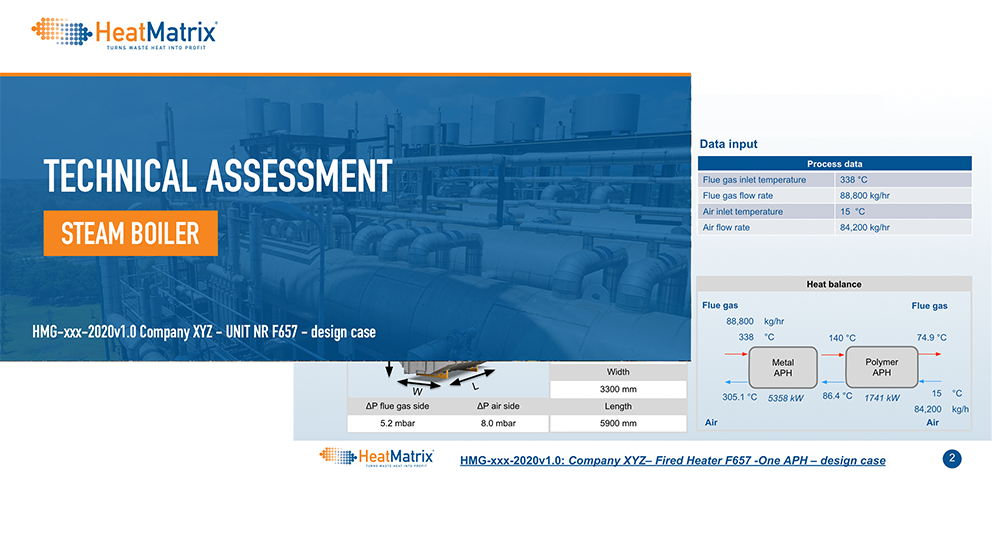

Technical Assessment of heat recovery on your Steam boiler

Our process engineers assess the technical feasibility of additional heat recovery on your Steam Boiler, or any other thermal process. Your potential reduction in CO2 emissions, energy consumption and costs is determined by our experts.

- Analysis of process data of your steam boiler

- Minimal input data required

- Business case on your savings potential