Waste heat recovery systems for flue gas and baking vapours in Bakeries

Do you need to reduce your energy consumption? Our experts determine your heat recovery opportunities and implement the best heat recovery system in your bakery.

Your oven, boiler or thermal oil heater is losing up to 20% energy via the stack or chimney

What is keeping you from recovering this waste heat?

Operational priorities?

You lack time to investigate energy saving possibilities.

Fouling baking vapours?

Vapours from your ovens may be greasy, sticky or may contain dust which causes heat exchanger blocking.

The business case?

The payback time of waste heat recovery systems must be less than 5 years.

HeatMatrix engineers and manufacturers heat exchangers to recover industrial heat and improve energy efficiency for Bakeries.

Save up to 10% energy on your thermal process

Recover waste heat - that is now lost - from flue gas or baking vapours

- Free Heat Recovery Scan

- Fouling resistant systems

- Payback time less than 5 years

- Turnkey project delivery

Your thermal process has waste heat recovery potential

Select your thermal process to find out how

Baking ovens

Up to 20% of heat from baking ovens is lost through the chimney. Heat from hot baking vapours and flue gases can be used to preheat air or water.

Steam boilers

Hot flue gas from steam boilers leaving the chimney still holds more than 10% of energy. This can be recovered and used to preheat combustion air, boiler feed water or cleaning water.

Thermal oil heaters

On thermal oil heaters 15% of energy is lost through the chimney. This can be recovered and used to preheat combustion air or water for cleaning and building heating.

How waste heat recovery systems work

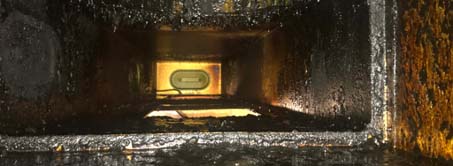

Capture waste heat

Hot baking vapours and flue gases are released to the atmosphere through the chimney. Our heat recovery system captures this heat from baking ovens, steam boilers or thermal oil heaters so it is not lost to the atmosphere.

Preheat air or water

Air, which is heated with the recovered heat, is used for your baking process or boiler combustion. The hot water is used for cleaning processes or heating of buildings. This directly reduces the consumption of fossil fuels.

Our waste heat recovery systems for Bakeries

Polymer Air Preheater

Our air preheaters with anti-fouling properties extract heat from flue gases or baking vapours to warm up combustion, convection or circulation air.

Polymer Economiser

In our economisers heat from flue gases or baking vapours can be used to heat make-up, boiler feed or CIP water.

Industrial Cookie Bakery

20% gas reduction

The industrial bakery has the ambition to reduce energy consumption. In the production process of cookies many fatty ingredients are used like butter and chocolate. In the oven fouling baking vapours are extracted and currently released to the atmosphere at high temperature. The bakery would like to recover heat from these vapours to reduce overall energy consumption.

Because of the smooth surface of the polymer tubes the HeatMatrix polymer Air Preheater has a low tendency to fouling. This aspect in combination with an in-situ cleaning system made it the perfect combination for heat recovery at this bakery. A polymer Air PreHeater was installed and cools down all the baking vapours from the oven.

Circulation air for the oven is preheated from 15 to 103°C, which results in a heat recovery of 143 kW and a reduction of the oven gas consumption of 20%.

Your path to lower CO2 emissions, energy consumption and costs

Technical assessment

Our process engineers assess technical feasibility of additional heat recovery on your process. The potential reduction in CO2 emissions, energy consumption and costs is determined.

Heat exchanger design and Business Case

Realize Project delivery

HeatMatrix will design, deliver and, upon request, install a complete heat recovery system on your site, so you don’t have to worry about the implementation.

FAQ's

How to save energy in a Bakery plant?

Bread or confectionary is baked in (continuous) ovens. The flue gases and baking vapors are sources of waste heat. The waste heat can be recovered and used for combustion or convection air preheating. Alternatively hot water can be generated for usage in (crate) washers, dough preparation or for building heating.

Will waste heat recovery influence my baking process?

In case of an Economiser, heat recovery will not influence your baking process because the equipment will be installed in a bypass with its own fan. This will ensure that the pressure in the ovens will not be affected. In case of an air preheater, our experts will analyse together with you how air preheating on your oven is feasible.

My ovens do not run continuously. Is a waste heat recovery system still an interesting investment?

When you operate your oven for more than 4500 hrs per year, it is very likely that a good business case can be achieved. Our proposal for a turnkey installation will contain an economic assessment of the project.

What is the minimum temperature required for the waste heat recovery system to work cost efficient?

Flue gas with a temperature of 120 °C can already be a cost efficient source of waste energy. Other variables that play an important role in the business case are the total flue gas flow and running hours of the oven.

How is fouling managed in the HeatMatrix waste heat recovery systems?

HeatMatrix heat recovery systems are easy to clean and maintain. Heat exchanger units can be easily removed for manual cleaning. An in-line cleaning system can be installed that cleans automatically during operation.

Payback time of waste heat recovery in a Bakery plant?

Typical payback time of waste heat recovery in industrial bakeries is in the range of 3-5 years. We can help in determining the most attractive combination of waste heat source and heat user to define the best business cases.

Technical assessment of waste heat recovery for your bakery

Our process engineers assess the technical feasibility of additional heat recovery on your process. The potential reduction in CO2 emissions, energy consumption and costs is determined.

- Analysis of your thermal process

- Minimal input data required

- Business case on your savings potential