Waste heat recovery from Steam boilers

Your Steam boiler has waste heat recovery potential

Improve boiler efficiency

Steam boiler efficiency can be improved to >95%, by using a polymer air preheater or economiser.

Lower CO2 emissions

Every 1% efficiency increase of your Steam boiler results in 1% CO2 emission reduction.

Decrease fuel costs

By recovering additional waste heat, less fuel is needed to achieve the required duty of your Steam boiler.

Waste heat recovery on Steam boilers is limited by corrosion and mechanical failures

8-12% of the energy is lost via the stack

Steam is the most important heat source in the industry. During steam generation a lot of energy is lost via the stack. A typical Steam boiler is already equipped with an economiser to preheat boiler feed water and will have an efficiency between 88 and 92%. This means that 8 – 12% of the energy is lost via the stack.

Cold Spot corrosion problems

Depending on fuel type, heat exchangers may suffer from cold spot corrosion due to relatively cold tube skin temperatures. This limits heat recovery. Enhancing further thermal efficiency is possible by installing a corrosion resistant air preheater or economiser which recovers additional heat from the flue gas. This results in extra energy savings.

Mechanical failure

Conventional heat exchangers suffer from mechanical failure due to stresses that are developed by thermal expansion. This results in leaking equipment and loss of heat recovery.

How to recover more waste heat from your Steam boiler

Use flue gas heat to warm up boiler feed water

The simplest and most economical way to improve the efficiency of your Steam boiler is by applying an economiser to preheat boiler feed water. In case of flue gases with high acid dew points the stainless steel or polymer economiser of HeatMatrix can be applied. This economiser is insensitive to acid dew point corrosion and can recover energy from your flue gas under harsh conditions.

Use flue gas heat to warm up combustion air

A second stage heat recovery could be air preheating with the polymer Air PreHeater. With a polymer APH the flue gas temperature can be reduced to 80 – 100 °C.

Heat recovery systems for Steam boilers

Polymer Air PreHeater

Heat up combustion air or drying air by extracting heat from flue gas. The air preheater is corrosion resistant & anti-fouling and is easy to maintain and clean.

Stainless steel or Polymer Economiser

Warm up boiler feed water, make-up water or process water with waste heat from flue gas. The economiser is corrosion resistant & anti-fouling and is easy to maintain and clean.

Carlsberg

4% boiler efficiency increase

Within the Together Towards ZERO program, Carlsberg strives to make their breweries more sustainable. One of the steps taken in their Ukraine brewery is using a biogas fired steam boiler.

Due to the usage of biogas, high concentrations of sulphur elements can be found in the flue gas. If the flue gas is cooled down, these sulphur components condense and form sulphuric acid which is very corrosive. To prevent this from happening, Carlsberg operated their system such that the flue gas was at a high temperature (>140 °C) leaving the stack. Additional heat present in the flue gas was not used.

HeatMatrix installed a polymer air preheater which allowed Carlsberg to cool to temperatures below the acid dew point and achieve additional heat recovery on their steam boiler. There are no corrosion issues because of the corrosion resistance of the polymer used in the HeatMatrix air preheater. Based on the success in Ukraine, Carlsberg Serbia introduced the same solution on their biogas fired boiler.

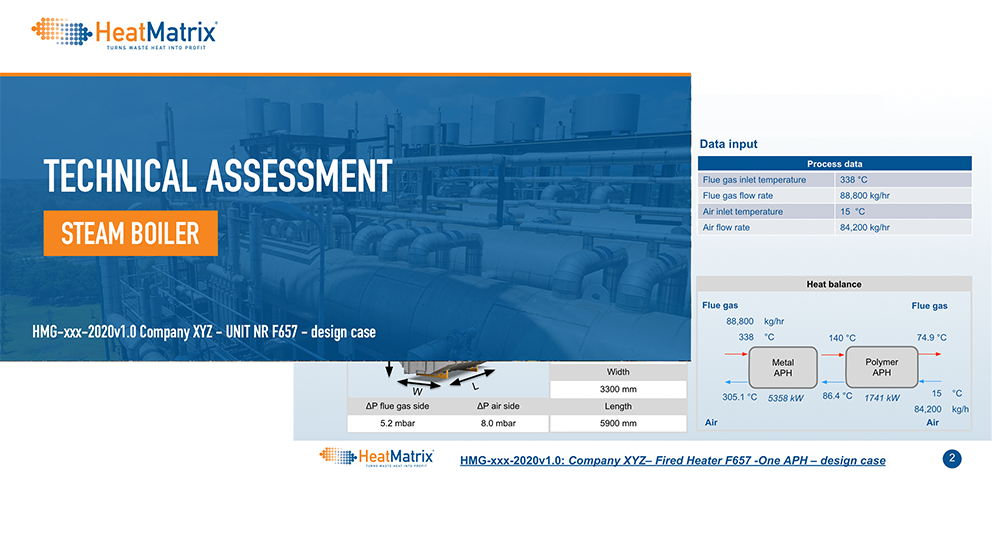

Technical Assessment of heat recovery on your Steam boiler

- Analysis of process data of your steam boiler

- Minimal input data required

- Business case on your savings potential

FAQ's about Steam boilers

How does an industrial steam boiler work?

An industrial steam boiler is a closed vessel in which water is present. Fuel (natural gas, oil, coal or biomass) is combusted in pipes that are in the water vessel. Hot gasses are produced. These hot gasses heat the pipes that are in the water vessel which transfers the heat to the water. Steam is produced in the boiler.

What are industrial steam boilers used for?

How does waste heat recovery on a steam boiler work?

In a steam boiler the heat from the flue gas is transferred to the water, which then turns into steam. Downstream of the boiler the flue gases are still high in temperature and are typically 50ºC or more above the steam temperature. Flue gas heat exchangers downstream the boiler can recover this waste heat and improve the boiler fuel efficiency.

Waste heat recovery options from a steam boiler?

For heat recovery on a steam boiler the following types of flue gas heat exchangers can be installed: a steam super heater, an economiser to preheat boiler feed water, an air preheater to preheat the combustion air, a condenser to heat-up make-up water or process water.

Benefits of waste heat recovery on a steam boiler?

Recovery of the waste heat on a steam boiler improves the fuel efficiency and reduces CO2 emissions. If the condensation energy can be recovered, a boiler efficiency above 100% can be achieved.